Braking systems have developed from mechanical designs to sophisticated electronic and hydraulic systems. The current level of vehicles, though, relies on high-level technology to generate stopping energy. There are different types of brakes, including mechanical or hydraulic brakes. The former typically rely on cables and levers to function. Hydraulic systems use fluid pressure to offer consistent braking. Understanding the manner these systems operate can also help drivers appreciate the engineering behind vehicle safety features.

Mechanical Braking System

Mechanical brake types use physical force as transmitted through levers, cables, and rods. A linkage pulls on the brake shoes when the driver presses the brake pedal. That causes friction against the drum, so it slows or stops the vehicle. This was a key feature in early vehicles but is still found in older cars and bicycles. Though simple and cost-effective, mechanical braking needs manual effort and is less efficient than hydraulic systems. This would make it more rare in current braking systems.

Hydraulic Braking System

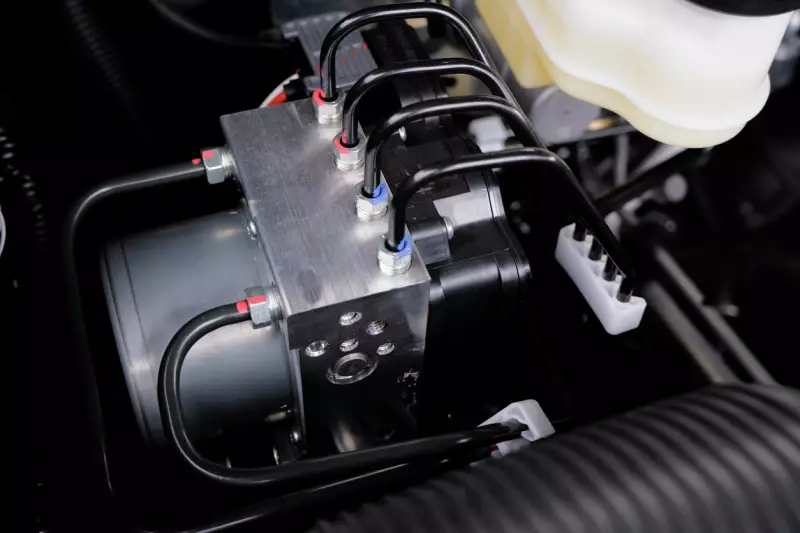

Hydraulic braking systems use fluid pressure transmitted through the brake fluid to convert the force applied on the brake pedal into the braking force required to stop the vehicle. It has a self-lubrication mechanism, which reduces the need for external lubrication. Given minimal effort, the system may deliver a high braking force that affords stopping power for vehicles.

Hydraulic brakes deployed in vehicles use hydraulic pressure. Their operation is based on Pascal’s law, which states that the pressure exerted on a confined fluid is transmitted equally in every direction, so there are effective braking mechanisms in different automotive applications.

Disc Brake System

Disc brakes form the standard for most vehicles. These vehicles typically use calipers and rotors to make friction, which slows the wheels down. When the driver also depresses the brake pedal, the caliper squeezes the pads against the rotating disc. This causes friction and slows the wheel’s movement. Friction also creates heat, but this is dissipated into the surrounding air.

Disc braking is more efficient than drum braking, and so it has become essential because of its superior performance. Disc brakes generally provide better heat dissipation abilities and increase the durability of the brain system. They are effective for heavy-duty trucks or sports cars.

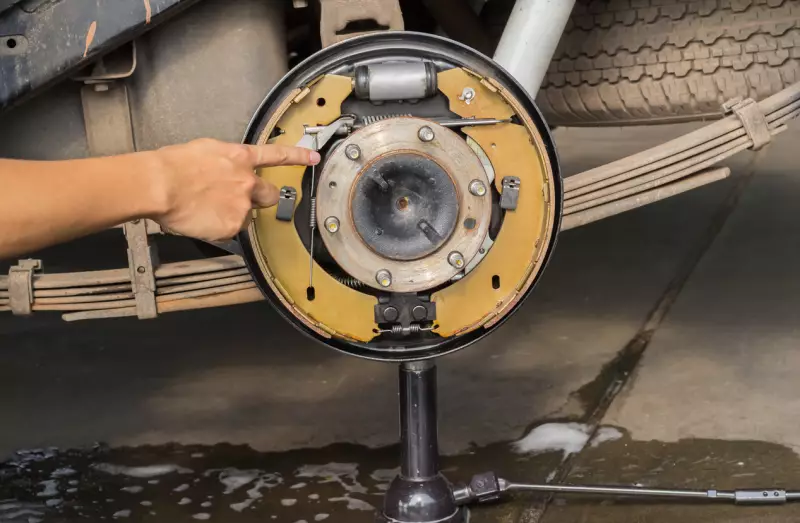

Drum Brake System

Drum brake types work by pushing the braking shoes against the inner surface of the rotating drum. This system includes a backing plate, brake drum, wheel cylinder, shoes, handbrake cable, and return springs. When a driver presses on the pedal, and the master cylinder initiates hydraulic pressure sent to the wheel cylinder. It is transferred from the pistons on the wheel cylinder, so they move out and apply the force on the shoes. The shoes transfer the same force on the surface of the drum, which slows the wheel down. When the driver releases the pedal, the hydraulic pressure reduces and decreases friction. This allows the wheel to continue moving unhindered.

Regenerative Braking System

Regenerative types of braking systems are typically found on electric vehicles or hybrids. The system operates by harnessing the energy generated when the brakes are in action. This heat is converted to electrical energy, which charges the high-voltage battery. Regenerative braking may complement traditional braking. The energy recovered would depend on the vehicle model and one’s driving behavior.

Anti-lock Braking System (ABS)

Anti-lock braking systems (ABS) are standard on most new vehicles and are designed to prevent the car from skidding during emergency stops. The wheel hubs of a vehicle with ABS have a sensor that can tell how quickly the wheel is rotating and the rate of acceleration or deceleration. When the driver brakes sharply, ABS senses when the wheels are about to lock. It rapidly increases and reduces the braking pressure multiple times a second to apply the right pressure. That allows the wheels to move as the car slows down instead of locking up.

Electronic Brake Force Distribution (EBD) and Brake Assist

Electronic brake force distribution is a safety system that optimizes braking by adjusting the force applied to every wheel according to road conditions, load, and speed. EBD helps to ensure that proportional braking is applied to each brake. During the braking process, the vehicle’s weight can shift to the front wheels so they have the greatest traction in most braking situations. ABD uses ABS sensors to detect lockup in the rear wheels to avoid problematic ABS cycling in an emergency. It then controls the ABS solenoids to reduce braking force on the rear wheels. This leaves maximum braking force to the front and maximum braking force and controllability.

Emergency Brake / Parking Brake System

The emergency brake system operates independently of the main braking system. It may also be referred to as the parking brake, which was initially designed to be used if the main braking system fails. While calling the auxiliary or emergency brake system a parking brake implies it is used every time the vehicle is parked, the name emergency brake suggests it is only for emergencies. That said, whether it is called a parking or emergency brake, it does the same thing and may be used in various scenarios.

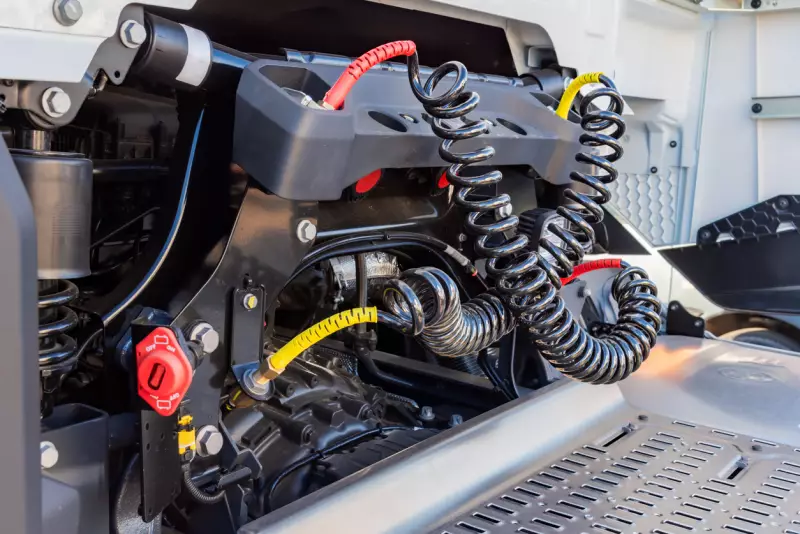

Air Brake System

Air braking systems are typically used in heavy vehicles like buses or trucks. This system works with an engine-mounted compressor. The compressor pumps air into the storage tanks, which store it until needed. Air pressure may be used to apply the service brakes and then release the parking brake. There are several air circuits in the system.

When air in the brake chamber is released, the brake engages using spring force in the parking brake part of the chamber. This may also allow the parking brake to be used as an emergency braking system. If the air pressure drops low, the force exerted by the spring will overcome the force exerted by the air on the diaphragm, and braking will be applied to every wheel.